Enthusiasts expecting more from their rides is not a new thing. We’ve been pumping up the power, performance, and various components of our rides since the evolution of the automobile. That has led to a needed increase in power from our vehicle’s electrical system to keep up with demand. More tech means more power is used. For many vintage car or truck owners, that means installing a high-output alternator to keep all those modern amenities well-fed.

The typical vehicle’s 12-volt electrical system has been the standard for decades, but the number of Amperes (amps) used has increased exponentially since those early days of sealed-beam headlights and “GEN” lights on our dashboards. Modernizing a vintage vehicle brings all the benefits, as well as the needed amperage increase to keep up with demand.

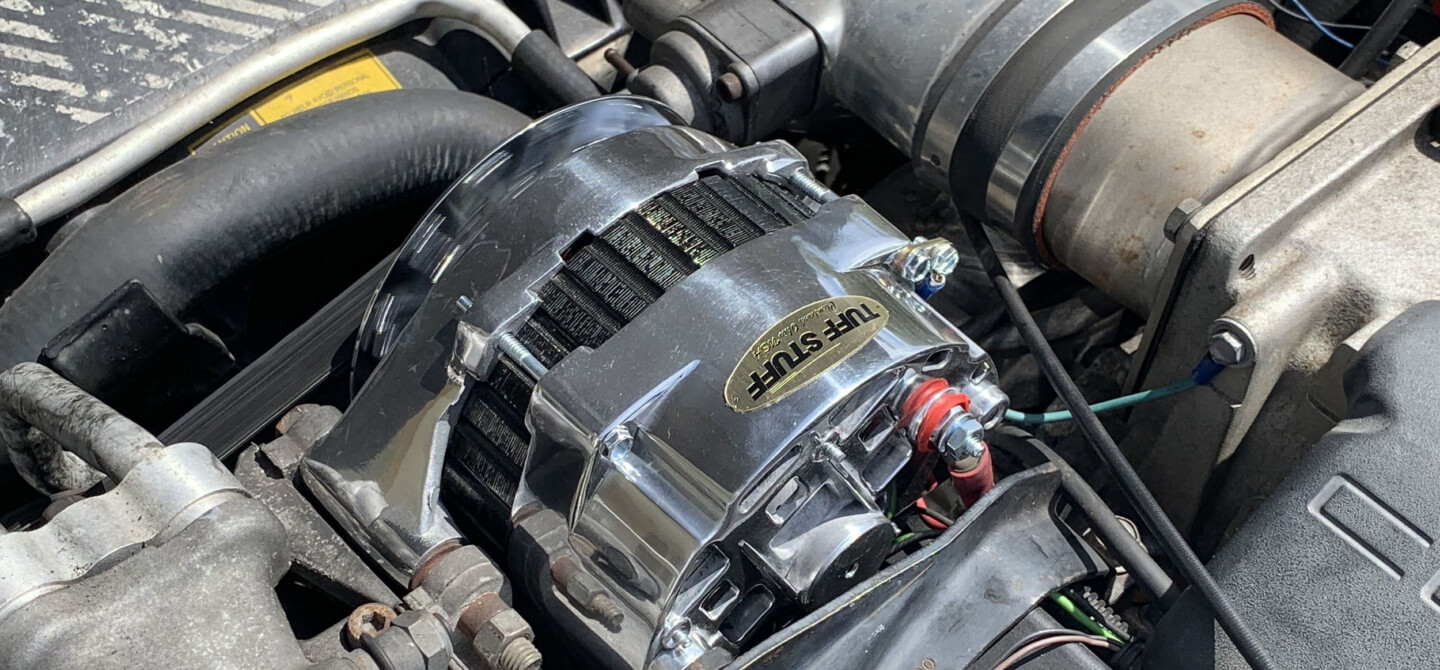

Tuff Stuff offers high-output alternators for vintage and late-model vehicles in various finishes. Knowing how many amps your vehicle needs will help you get the perfect alternator for your application.

We’ve illustrated the benefits of an updated charging system many times, but we’ve also heard some of the concerns that enthusiasts have about updating to a high-output alternator. With the help of the knowledgeable staff at Tuff Stuff Performance, we’ll address some of these concerns and explain why they are unfounded, so long as you do the upgrade correctly.

How Many Amps Do You Need?

There are some foundational truths about the “charging” system in your auto. Firstly, it’s only designed to maintain the battery. Sure, if working properly, it’ll restore a battery from a high-draw, engine-starting situation, but it’s not designed to bring a battery back from a completely discharged state. Next, understand that a properly working vehicle’s charging system will only supply as many amps as the system needs during operation.

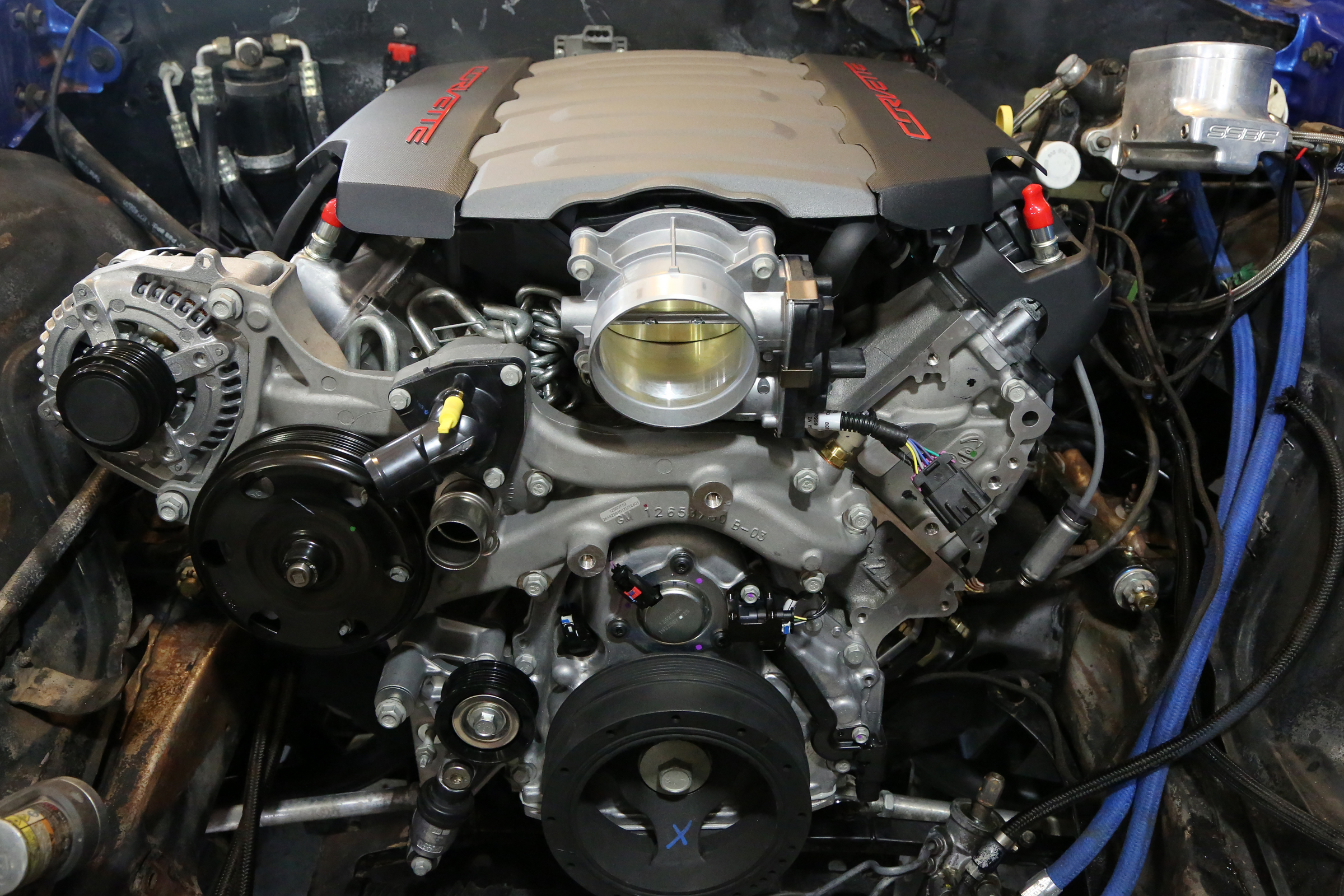

The 12-volt automotive electrical system has been the standard for decades, but it should have more than 12 volts when operating. Our meter shows 14.14 volts, but will the battery go into discharge with electric fans, A/C, lights, and the blower motor all running? Testing the amperage use with all the power accessories working will let you know how many amps are needed.

The purpose of updating to a high-output alternator is to garner more amperage when you need it. An alternator’s maximum output is the most amperage it can supply at higher revolutions, but a typical OEM or one-wire alternator will only produce approximately 50 percent of its maximum output at idle. It’s also worth noting that while a high-output alternator may be able to put out over 200 amps at max output, it will only produce as many amps as needed by your vehicle, at any speed.

We prefer the charging cable to be mounted as short as possible and directly from the alternator to the battery positive terminal for the best connection and operation. – Matt Oliver, Tuff Stuff Performance

As you increase the number of energy-hungry components, such as electric fans, stereo amplifiers, and additional lighting, the number of amps needed will increase as well. To determine if you need a high-output alternator, you need to know how many amps your vehicle uses in various situations. The best way to find that number is to test the system with all these components operating – that means the A/C on, engine running, cooling fans operating, etc. You may find that your vehicle needs a higher-output alternator, especially at idle when the cooling fans turn on at stoplights and such.

Can A High Output Alternator Damage Other Components?

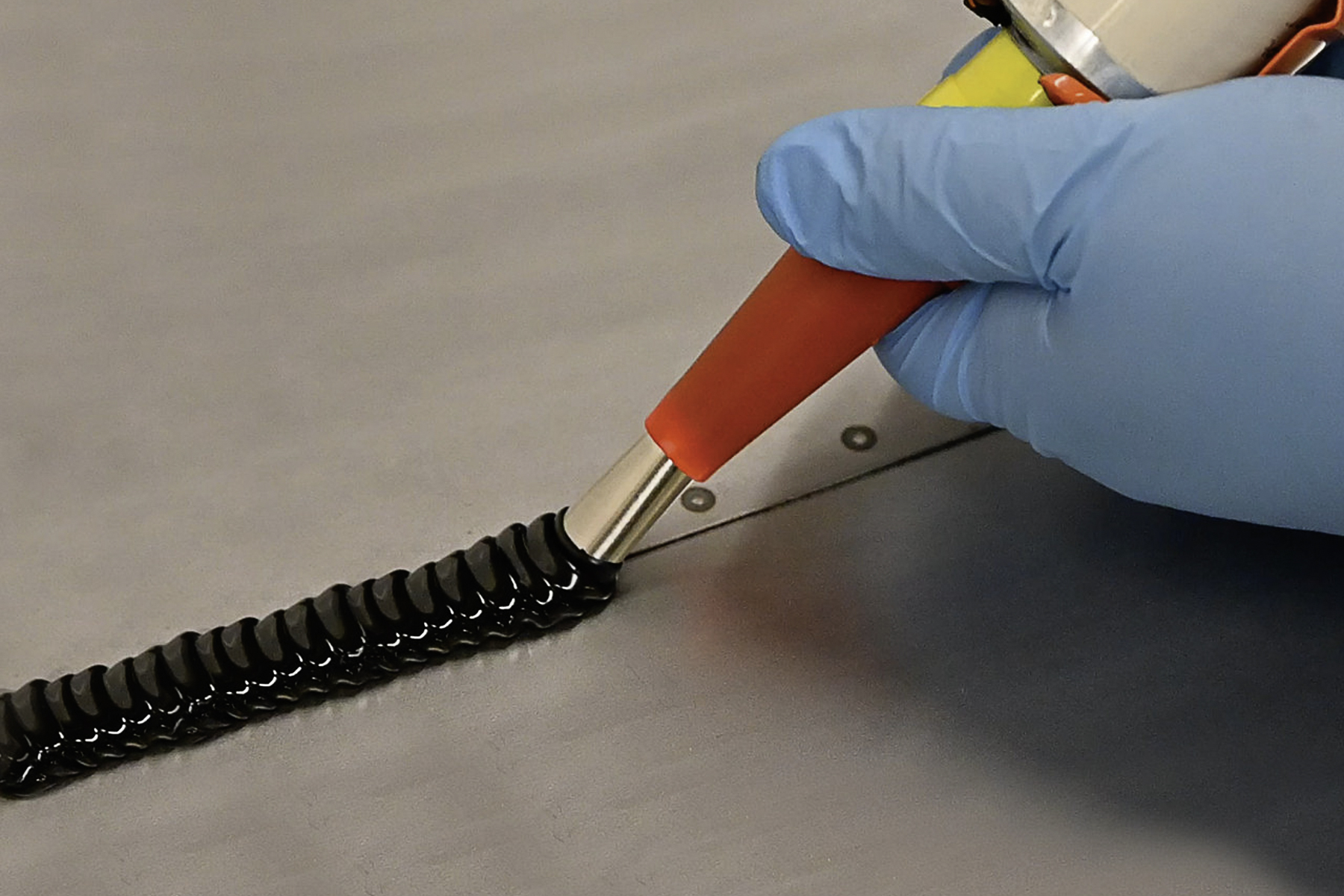

We’ve heard several concerns about increasing the amperage potential of the alternator, but if you look at your vehicle’s charging system as a complete system and not a component, these concerns are unfounded. One of the main concerns enthusiasts have about upgrading to a high-output alternator is heat, which is directly connected to the amount of resistance throughout the system. Each loose connector and aging strand of inadequately sized wire can increase resistance to the point that damage could result. It’s always a good idea to ensure all wires and connections are up to the task, whether upgrading your charging system or not. Simply having a quality harness could make a huge difference in keeping your battery charged.

Tuff Stuff offers a variety of charging cables to fit most applications.

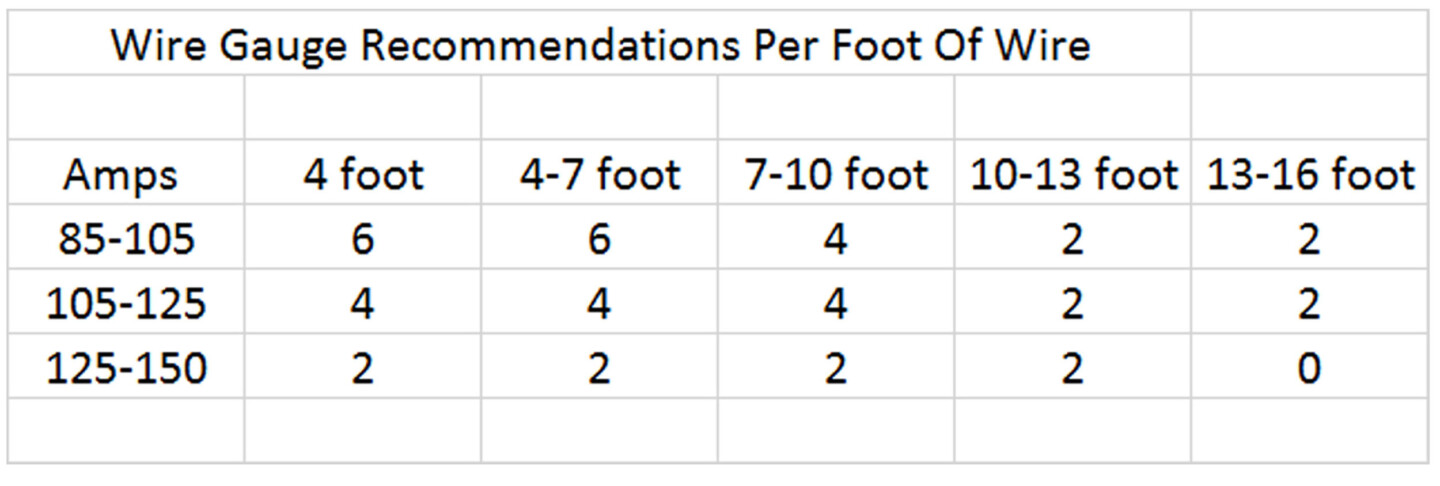

The charging system in many vintage cars and trucks was wired with 14- to 16-gauge wires designed to handle only the 45- to 60-amp output of the OEM alternator. When upgrading to either an OEM-style or one-wire high-output alternator, you should also update the charging wire that feeds all those amps back into the battery. Matt Oliver, Tech Manager for Tuff Stuff Performance, explains that this is the biggest mistake when enthusiasts upgrade to a higher-performing alternator.

As the number of amps and length of the charge wire increases, the size of the wire used must increase as well.

You also need to consider that the vehicle’s charging system has a positive and negative (grounding) component. That fancy, new high-output alternator won’t work at all if it’s not properly grounded. Grounding the alternator’s body to a clean, steel engine mount will typically accomplish this if the engine is also grounded properly. Each Tuff Stuff alternator also includes a grounding tab that can be used to ground the alternator’s body directly.

What’s The Difference Between A One-Wire Alternator And The Alternatives?

We’ve previously discussed whether upgrading to a one-wire alternator is the right choice. One argument that keeps coming to the surface is when a one-wire alternator begins charging (gets excited). Matt explains it clearly: “All one-wire alternators will not start charging until around 900 RPM,” he said. “That is the lowest RPM we’ve been able to achieve, but once it’s excited, it will continue to charge, even at idle.” He also states that all OEM-style (non-one-wire) alternators are designed to start charging almost instantly, if that is a concern.

Tuff Stuff High-Output Alternator Testing

Tuff Stuff takes charging seriously and recently invested in all-new testing equipment to verify the output of its newest line of high-output alternators. Every alternator Tuff Stuff manufactures spends time on this testing equipment. Alternator output is documented from idle, throughout multiple speeds while various loads are applied during the approximate one- to two-minute testing cycle. This testing procedure verifies each alternator’s voltage regulator cut-in speed and maximum amperage rating. Tuff Stuff’s testing equipment can verify the output of alternators capable of producing 300 amps at speeds up to 10,000 RPM.